Corrosion

Table of Content |

Introduction to Corrosion

The word Corrosion comes from a Latin word Corrosionem.

It is known as slow eating of the metal surface.

It is the irreversible disintegration/fragmentation/destruction of metal by an unintentional chemical or electrochemical reaction with their environment. It generally starts from surface.

It is an oxidation process of redox reaction.

It is an example of spontaneous natural process in which a refined metal is converted into a more stable chemical form like Oxides, Hydroxides, Sulfides, Carbonates etc.

It can be referred as a universal phenomenon, omnipresent and omnipotent. It is there everywhere like Air, Water, Soil and in environment we encounter.

For Example: When we see a rusted, shoddy old car in garage the culprit behind it is corrosion.

Causes of Corrosion

Few Important Causes Behind Corrosion are given below:

-

Reactivity of metal-Highly reactive metals corrode faster.

-

Presence of impurity-Presence of salts like NaCl etc acts as catalyst to corrosion.

-

Presence of air, moisture, gases like SO2 and CO2 near metal.

-

Presence of electrolytes.

-

Characteristics of water in contact.(Like alkalinity of it / presence of ions / hardness / pH etc.)

-

Bacteria in surrounding (It’s presence increase O2 concentration near it.)

Tyres of Corrosion

|

Example(s) |

Type(s) |

|

I. Uniform corrosion

|

|

|

II. Galvanic corrosion:

|

|

|

III. Concentration cell corrosion:

|

|

|

IV. Pitting corrosion:

|

|

|

V. Crevice corrosion:

|

|

|

VI. Filiform corrosion:

|

|

|

VII. Intergranular corrosion:

|

|

|

VIII. Stress corrosion Cracking:

|

|

|

IX. Corrosion fatigue

|

|

|

Corrosion Seen Around Us

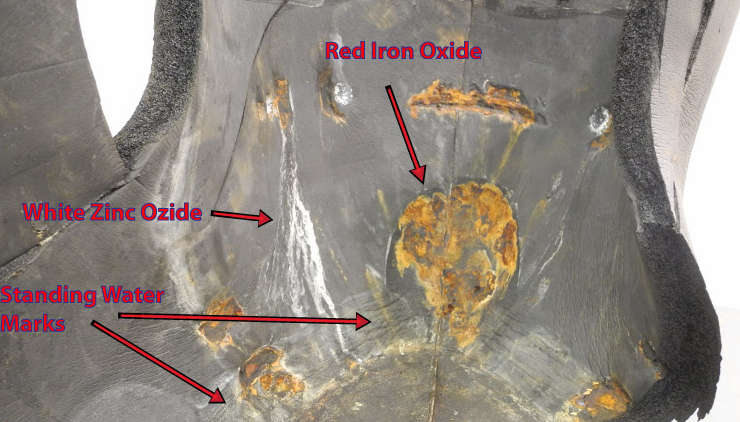

Rust is the product of a natural process called rusting commonly seen on reactive metal like iron. Rusting is the slow irreversible process which turns iron into iron oxide. It takes place when iron comes in contact with air and water.

Rust Mechanism is Depicted Below:

Rust Formation Reaction:

- Greenish Color of Copper Pot:

When copper is left out in contact with air and moisture it get tarnished and develop greenish color (due to copper hydroxide and copper carbonate) known as Patina.

General reaction : 2Cu + H2O + CO2 + O2 → Cu(OH)2 + CuCO3

NOTE: Unlike rusting in iron which is not good for it patina is a blessing in disguised because it protects the copper underneath.

- White Powder Formation On Zinc

It is called White Rust or White Storing Stain. Pure Water lacking oxygen gas accelerate it.

General Reaction: ZnO + 2HCl → ZnCl2 + H2O

- Blackening of Tin Can

General Reaction: SnO2 + 2NaOH + 2H2O → Na2[Sn(OH)6]

Prevention of Corrosion:

Corrosion is like a hidden villain which forces a country GDP to fluctuate around it. Because if a bridge is manufactured 20-30 year back using steel bars, with time the bridge strength keeps on decreasing due to corrosion and need constant check and repairs and sometime replacement’s. Due to Corrosion automobile industries suffers a major loss because the roofing and flooring get affected badly with timing and need repair and replacements. Even household goods like grills, doors, railing etc need to be painted regularly with time.

We can relate corrosion to cancer because once it starts we cannot stop it, only we can reduce its rate.

Methods to prevent rather to avoid corrosion are:

-

Environmental Modification: Reduce or decrease the presence of those factors which causes corrosion near the metal surface. Like Park the car in garage and avoid its direct exposure to direct sun light, moisture, rain and large quantity of oxygen.

-

Painting: Metal surfaces like grills,chairs,tables made up of iron are painted so that its direct contact to moisture and oxygen is reduced and rate of corrosion is reduced.

-

Greasing/Oiling: Ball bearing, cycle chain etc. are greased regularly to avoid corrosion by cutting its contact with environment.

-

Galvanization: The method in which a reactive metal like zinc is coated on Iron or steel surface so that it will be corroded by atmospheric condition and finally protect the iron or steel layer below. Also called sacrificial protection.

Other Methods are also used like:

-

Electroplating

-

Cathodic protection

-

Anodic protection

-

Metal selection and surface condition

-

Controlling temperature, chloride concentration and PH

-

Use of better alloys like ASTM G-48

-

Addition of corrosion inhibitors

|

|

|

Some Harmful Effects of Corrosion

-

Metal loses its natural efficiency

-

It contaminate pure metal/material sample.

-

Damaging of equipment’s like motor parts etc

-

Blockage of pipes

-

Accidental damages seen in defected bridges, rail tracks etc.

-

A source of pollution due to the different types of gas evolving due to it.

-

Depletion of metal natural resorce.

-

Corrosion of prosthetic medical implants like tooth braces, pacemaker, rods or clips is dangerous to health.

-

Corrosion can destroy historical monuments like the one we see on iron pillar in Delhi which was built in mogul era.

-

Release of toxic products from corroded tanks in chemical industries.

|

|

Merits of Corrosion

-

Some corrosion on surface forms oxide layer on it and this layer act like a film or barrier for air or moisture thus protecting the metal below it.

-

Few metals like zinc behave like sacrificial anodes to avoid corrosion to other metals.

-

Galvanic corrosion is the fundamental basis behind use of batteries. Here, two metals rods like that of zinc and carbon are knowingly mixed together in an electrolyte solution where zinc corrodes faster in order to generate electrical charge.

-

Metal like aluminum undergoes surface corrosion and produce an oxide layer on it which protects the metal from being consumed by corrosion.

Watch this Video for more reference

View courses by askIITians

Design classes One-on-One in your own way with Top IITians/Medical Professionals

Click Here Know More

Complete Self Study Package designed by Industry Leading Experts

Click Here Know More

Live 1-1 coding classes to unleash the Creator in your Child

Click Here Know More